Received: 01-Jul-2022, Manuscript No. GJDFM-22-73193; Editor assigned: 04-Jul-2022, Pre QC No. GJDFM-22-73193 (PQ); Reviewed: 21-Jul-2022, QC No. GJDFM-22-73193; Revised: 29-Jul-2022, Manuscript No. GJDFM-22-73193 (R); Published: 05-Aug-2022, DOI: 10.15651/2449-1861.22.7.076

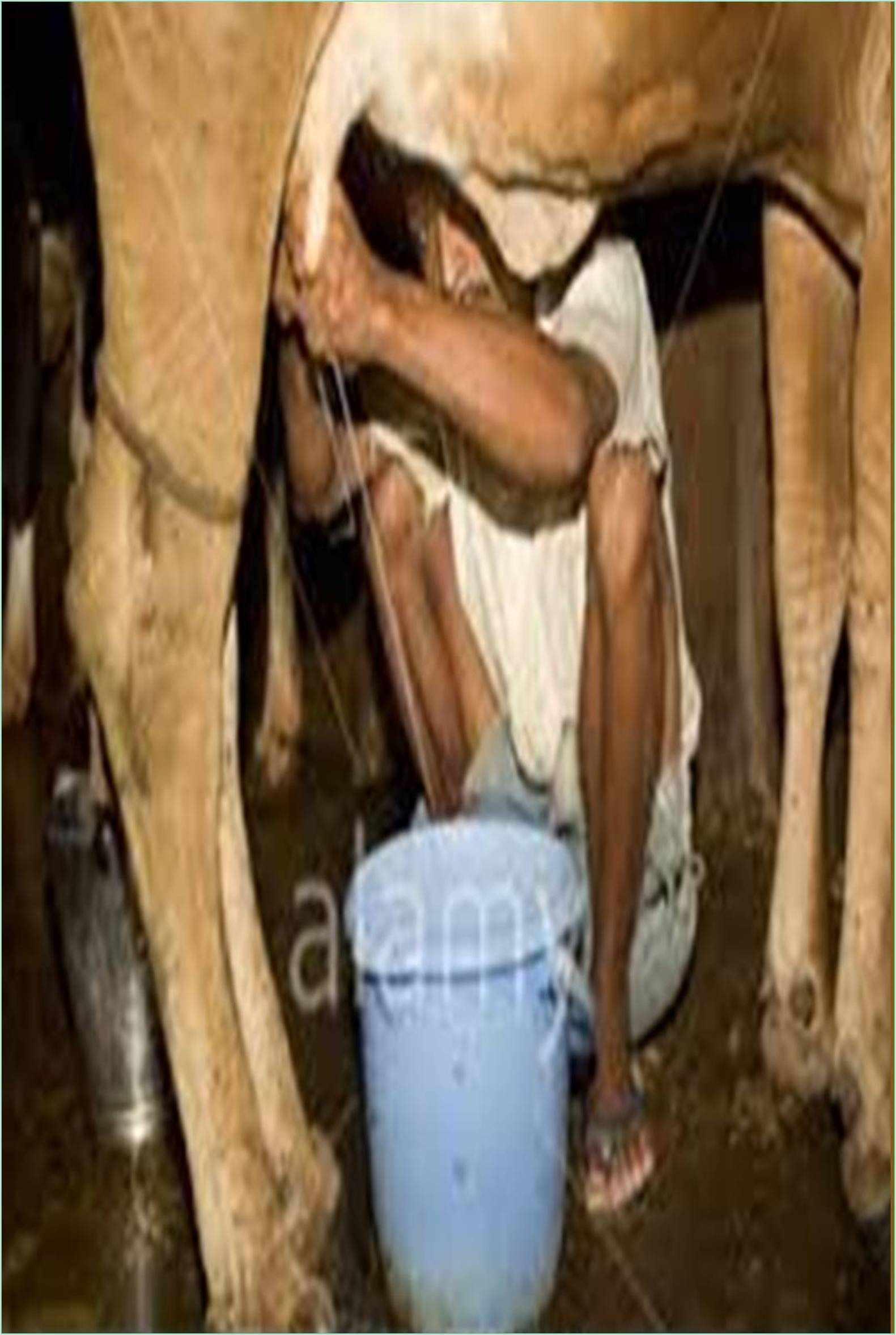

Milk, a secretion of the mammary glands of mammals, typically cows (bovine), sheep, goats, buffalo, mares, camels, or yaks, is the source of dairy goods. The majority of dairy products are made from cow's milk, with smaller amounts coming from sheep's and goat's milk. The water content of milk, which ranges from 80 to 90 percent, makes it vulnerable to unfavorable microbial growth and subsequent product deterioration. Milk is processed to create a variety of products, such as ice cream, cheese, milk powders, yoghurt, butter, lactose, and anhydrous milk fat, to avoid this issue from happening and to provide a longer shelf life (also known as butter oil).

By using separation, a centrifugation technique, milk can be divided into two fractions: cream and skim milk. Through this method, the milk's fat is concentrated into the cream phase, leaving a skim or partially skimmed phase with significantly less fat. Different cream fat contents can be obtained by varying the centrifugation speed. To enable longer storage of dairy products, various preservation procedures are applied during milk processing. Concentration to eliminate some of the water, atomization into a fine mist, and high-temperature drying are the steps used to create milk powder. For milk powders to have an extended shelf life, heat and dehydration are used. Ice cream is a dairy product that has been frozen to preserve it.

Both cheese and yoghurt are fermented foods. Milk is inoculated with a bacterial culture, which has the main purpose of lowering the pH from 6.7 (normal for fresh bovine milk) to 4.2 for yoghurt and in the range of 4.6 to 6.0 for the majority of cheese kinds. Additionally, the bacterial cultures help the milk product's proteins and fats break down so that part of the flavor can be developed. The additional bacterial culture's preservation role is to compete for nutrients with undesirable pathogens. Dehydration, acidification, and pathogen competition serve to preserve dairy products like cheese and yoghurt.

The minor organic components in milk include phospholipids, organic acids, enzymes, hormones, vitamins, nucleotides, amines, amino acids, alcohols, aldehydes, ketones, and esters. Milk also contains proteins, fat, water, lactose, and inorganic salts. To forecast how milk processing conditions affect flavor, texture, and the keeping properties of dairy products, it is crucial to understand how the key components of milk are structurally structured in milk.

The health of the cow is one crucial component in milk quality that has significant effects on dairy processing. Mastitis is an udder infection that causes milk to have a high somatic cell count. Mastitic milk has higher quantities of immunoglobulin but lower levels of fat, lactose, casein, and whey protein. Antibiotics are necessary for mastitis treatment, but they also have the unintended consequence of eradicating bacterial cultures that were introduced during the production of cheese and yoghurt.

The milk fat globule membrane and the separation of milk lipoprotein lipase from the milk fat substrate help to partially preserve fresh milk against lipolysis. Milk lipoprotein lipase is primarily linked to casein micelles. As was already mentioned, stirring milk encourages lipolysis. Within twenty-four hours, fresh, unpasteurized milk that has been heated to 86°F (30°C) and then cooled to fridge temperatures will begin to get rancid. This issue will arise if warm new morning milk is added to already-cooled evening milk from the day before, then the mixture is once more allowed to cool. In addition, after milk is cooled to 59–68°F (15–20°C), one in five cows have spontaneous lipolysis. Mixing with four to five times the volume of regular milk helps to solve this issue. Milk that has been frozen and thawed can also help lipolysis. The rate of lipolysis will rise as the freezing rate slows.