Published: 30-Dec-2021

Guaranteeing rigid temperature control boundaries and effective cooling systems are kept up with at a dairy plant are basic to downstream handling abilities and item quality. This study analyzed the temperature of approaching crude milk across three creation months to catch top season handling at one dairy fabricating plant. Across the review region, the normal temperature of approaching milk was 6.18°C. After the underlying cooling step in the dairy office, the normal temperature of put away crude milk was 4.74°C, with a normal cooling execution of -1.44°C. This exploration features interestingly, the investigation of a tight yet significant quality advance in milk handling plant, to be specific the basic rules of temperature observing and stream rate the executives at a dairy handling office.

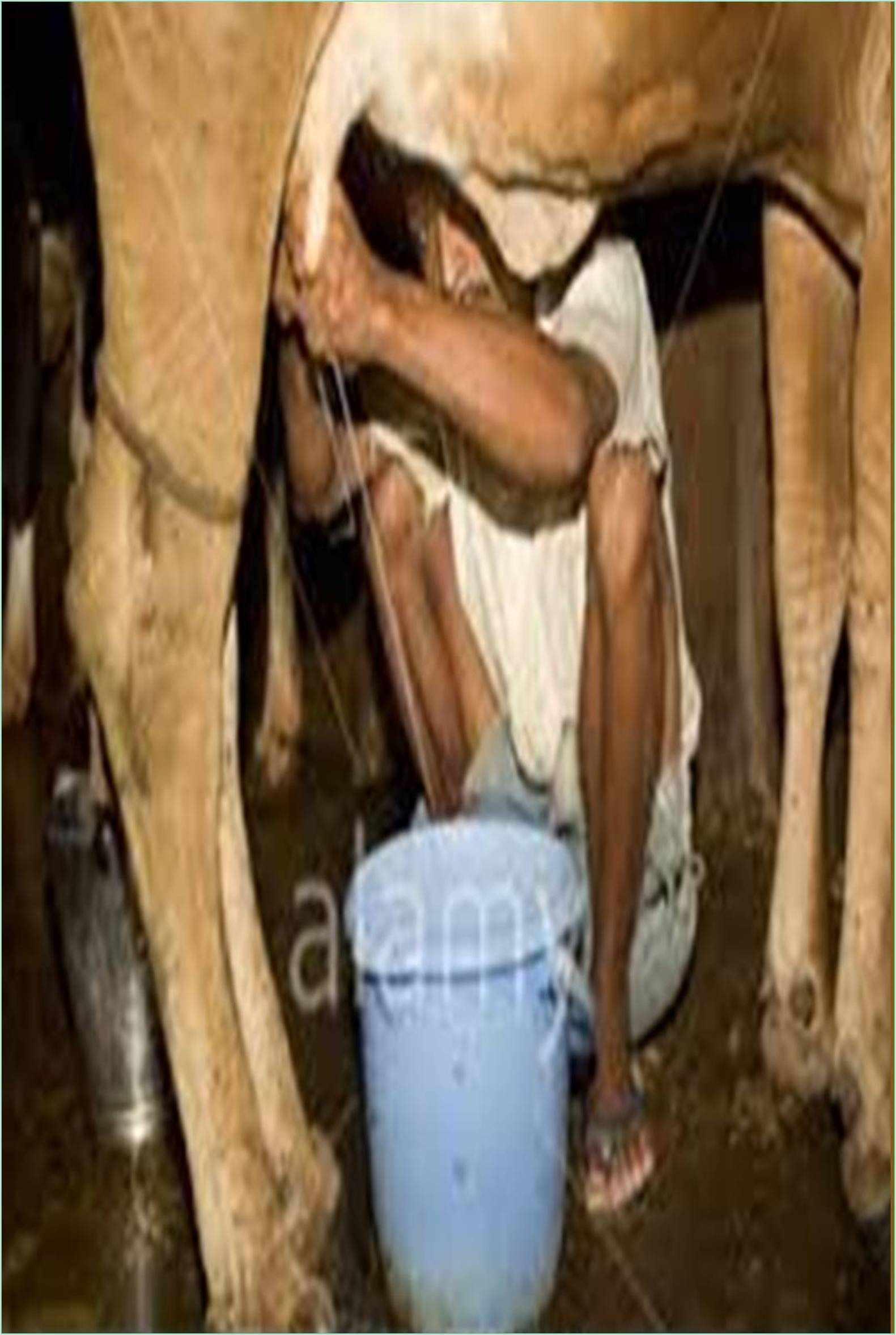

Temperature the executives of the crude milk production network is a key presentation marker at dairy handling plants. European Union regulation, permits a milk handling plant to gather milk on ranch up to 10°C and it expects milk to be cooled and put away to a temperature of something like 6°C until additional handling. Milk is basically sterile once orchestrated in the mammary organ of a sound cow and sterility is reduced once the creature has been drained. Day by day milk assortment isn’t reasonable for huge dairy plants and as the temperature of milk leaving the udder at 35°C is exceptionally good for bacterial development, cooling and keeping up with the temperature of crude milk from that point is fundamental in keeping away from an expansion in microbial burden.

After crude mass milk shows up at an assembling plant it should go through a set-up of administrative and quality tests before it is siphoned through Plate Heat Exchange (PHE) units and put away in storehouses until additional handling. A composite example from every truck compartment is tried for Somatic Cell Counts (SCC), Total Bacterial Counts (TBC), sharpness and anti-toxins. SCC levels in milk are associated with group wellbeing and can ascend with temperature increments. Uncontrolled SCC levels in milk can extensively decrease protein and fat recuperation and at last diminish yields, especially in cheddar creation. It is assessed that Gram-negative microflora represents over 90% of the complete psychrotrophic crude milk microflora. Thermophylic microscopic organisms can likewise be unfavorable to the development of dairy items guaranteed temperature assumes a significant part in the arrangement of biofilm, a microbial populace that sticks to a strong surface. Biofilm develop can be challenging to wipe out even with severe cleaning set up programs. On the off chance that bacterial development isn’t captured right off the bat in the creation chain, it might bring about exceptional reason variety in an assembling interaction and end result quality will be compromised.

This concentrate on quantitatively surveyed the approaching crude milk temperatures and cooling execution across three milk admission coves at one dairy producing site for a three-month time span. The results of this study gave the dairy producer the capacity to reevaluate their siphoning plans concerning utilization recurrence on individual siphons to enhance both stream and chilling execution. This exploration ought to urge any dairy maker to examine their on location chilling execution and siphoning frequencies at admission sounds.