Received: 01-Nov-2022, Manuscript No. GJDFM-22-82678; Editor assigned: 03-Nov-2022, Pre QC No. GJDFM-22-82678 (PQ); Reviewed: 21-Nov-2022, QC No. GJDFM-22-82678; Revised: 30-Nov-2022, Manuscript No. GJDFM-22-82678 (R); Published: 07-Dec-2022, DOI: 10.15651/2449-1861.22.07.080

Milk fat in the form of cream, butter, and ghee plays a key role in the Indian diet, helping to nourish people of practically all age groups. The fat-soluble vitamins A, D, E, and K are present in these goods in good amounts. According to ancient Vedic literature, ghee made from cow milk has high nutritional and tonic properties that are especially helpful to people recovering from chronic illnesses and bone fractures. Since the dawn of time, people have known cream component rich in fat as the fatty layer that, when milk is not disturbed, rises to the top of the container. Cream comes in a wide range of varieties. Although it serves a variety of functions, its superior flavor and body texture make it more of a luxury than a need.

Cream is milk fat that has been condensed into a small volume of the original milk. Cream can also be defined as a portion of milk that is high in milk fat, a portion of milk into which fat has been gathered and which contains a significant amount of milk fat, or any combination of these.

Cream, excluding sterilized cream, is a milk product made from cow or buffalo milk, or a combination of the two, and contains at least 25% milk fat. Depending on the amount of fat in the cream, the contents of the energy-giving fat and fat-soluble vitamins A, D, E and K are abundant.

Categorization

Cream is not a clearly defined material. All the components of milk are present, although in different amounts. Different fat contents are used in the production of cream sold to consumers. Cream with a reduced fat percentage, between 10% and 18%, is frequently referred to as half cream or coffee cream and is increasingly utilized in cooking and sweets. In general, cream with a higher fat content 35 to 40% is much thicker.

Whipping cream is the term used to describe a substance that can be beaten into a thick froth. Cream may include between 10% and 75% milk fat.

Generally, there are two types of cream: market cream, which is used for direct consumption, and manufacturing cream, which is used to make dairy goods.

The numerous varieties of cream include:

a) Table cream

b) Pale cream

c) Cream coffee

The average density of milk fat is 0.93 at 160°C and skim milk is 1.036. Due to their different densities, cream and skim milk stratify from one another when milk, which can be thought of as a mixture of fat and skim milk, is exposed to either gravity or a centrifugal force.

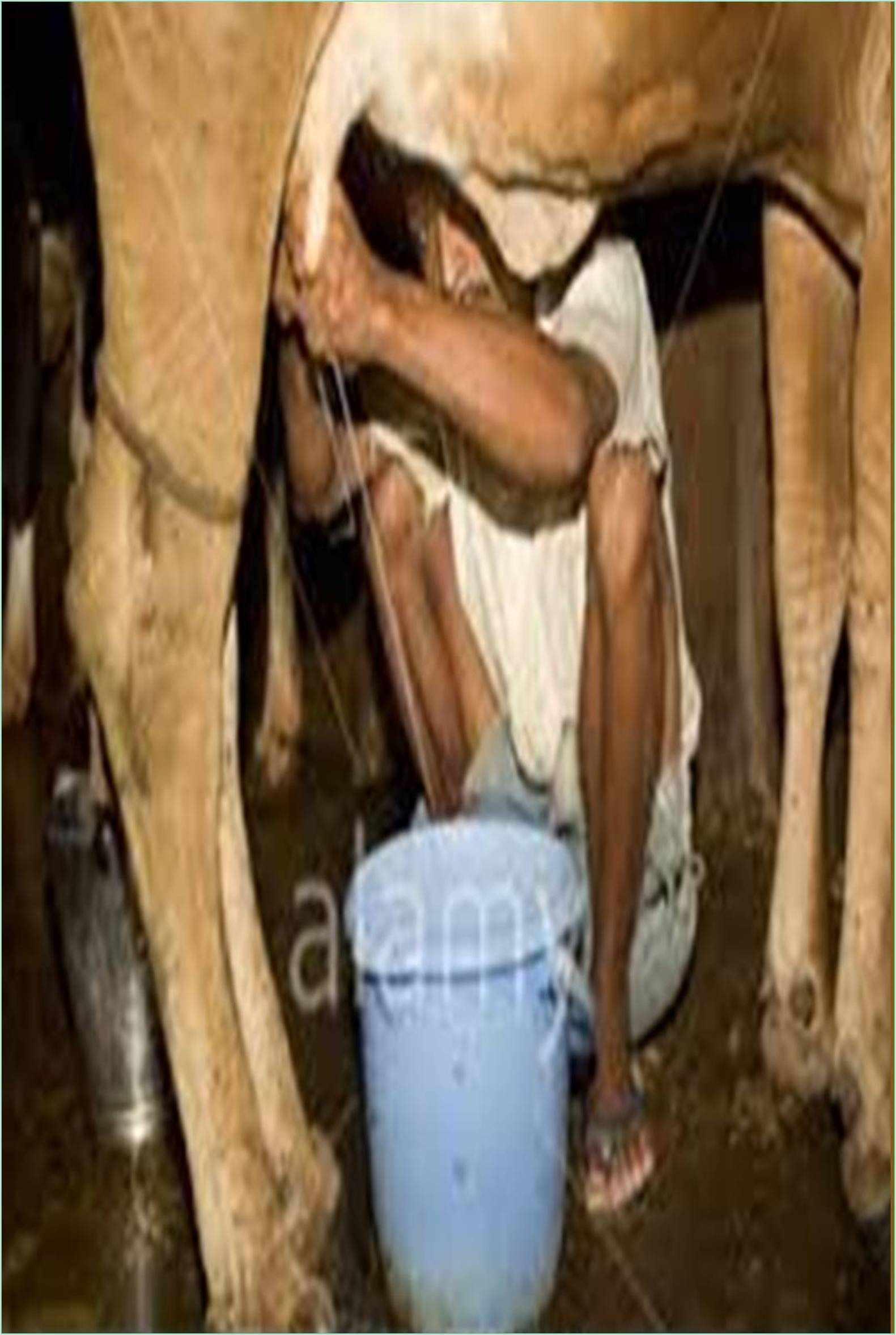

Commercially, cream is separated from milk using centrifugal force. Milk is immediately subjected to a centrifugal force that is 3000 to 1600 times stronger than gravity force as it enters the quickly rotating bowl of the cream separator.

Despite the fact that both fat and skim milk are subject to centrifugal force, the heavier portion of the milk is more affected by the difference in density and is pushed to the periphery while the fat portion moves towards the centre.

A partial reduction in acidity is suggested by the terms "cream neutralisation" and "sour cream neutralisation." Neutralizing cream defends against the development of an undesirable off-flavor in cream, avoids fat loss in buttermilk caused by churning excessively acidic pasteurised cream, and improves the butter's ability to keep for a longer period of time. Commercial storage of salted acid butter at -23°C to -29°C results in the development of a fishy flavor. Commercially available neutralizers include calcium and sodium bicarbonate.

Cream standardization

This refers to the cream's fat content being adjusted to the required percentage while still adhering to industry standards. By adding skim milk or cream, the fat content of cream is changed to the desired amount. The ideal cream fat content for creating butter is between 33% and 40%. Standardization to higher and lower levels causes butter milk to lose more fat.

Cream Pasteurization Cream is heated to 710°C for 20 minutes in a batch process and to 95 1000°C for 15 seconds in a High Temperature Sterilization (HTS) pasteurizer. Pasteurization is mostly performed to kill pathogens, inactivate enzymes, remove gaseous tainting agents, and eliminates volatile off tastes.